In-House Machining Facilities

PGSPL is well equipped with state of the art CNC machinery.

Our manufacturing operations are housed in a clean, temperature-controlled roof facility which provides the environment in which sophisticated, precision manufacturing can be achieved.

Our Machining facility includes CNC Turning, VMC, Plano Miller, VTL Conventional Lathes, Radial Drilling Machine, Semi-Auto Band Saw, etc.

We proudly continue to provide our clients & partners with the Precision Machining Services & On-Time Results that they have always trusted.

| Machining facility | Capacity |

| VMC | 1400mm (X) x 630mm (Y) x 610mm (Z) |

| VTL | Swing Dia: 900 mm, Z: 750mm by Aug-2020 |

| CNC Plano-Miller | 4200mm (X) x 2760mm (Y) x 800mm (Z) by Aug-2020 |

| CNC Turning | Turing Dia- 350 mm, Turing Length: 550 mm |

| Conventional Lathe | Turing Dia.: 750 mm, Max. Turing Length: 6000 mm |

| Automatic Band Saw | 300mm Square/ Round |

| Radial Drill | Ø52mm & Ø60mm |

| Plate Rolling Machine | 32mm Thk x 2500 mm wide |

Materials Handled

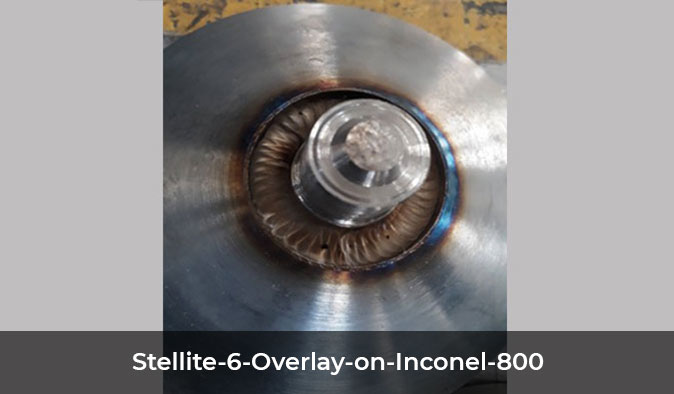

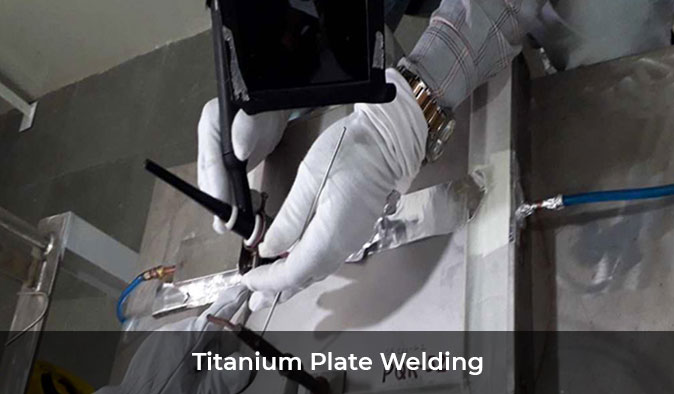

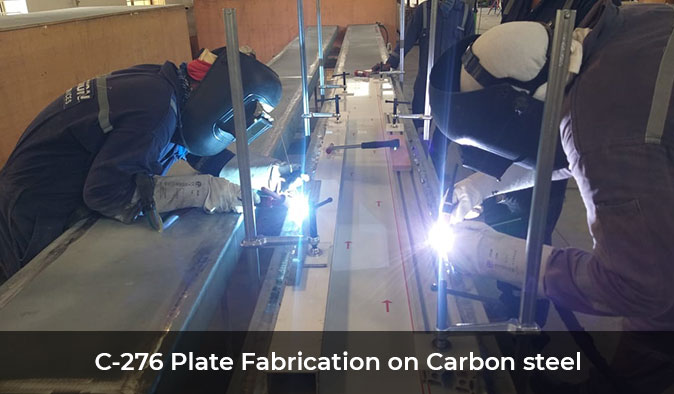

At Precision Gasification Services Private Limited, Our expertise lies in our reputation to Design and Fabricate cost-effective process Equipment Internals using the Exotic Metals. We possess and maintain dedicated areas in our facility for the fabrication of exotic material. We have well-developed welding procedures & Our team has worked on varieties of Exotic material like SS Grade, Duplex, Super Duplex, Alloy Steel, Inconel, Monel, Hastalloy C-276, Stellite, Carbides etc. We also carry out HVOF Coating on Critical Components for Petro-Chemicals Refinery Equipment.

At Precision Gasification Services Private Limited, Our expertise lies in:

| SS/Alloys | Inconel | Exotic Metals | Carbides |

| SS 304/L | Inconel 600 | Haynes alloys |

Tungsten Carbide |

| SS316/L | Inconel 625 | Titanium | Ceramic Carbide |

| SS310 | Inconel-800H/HT | Cobalt Alloys | Silicon Carbide |

| Alloy 20 | Inconel 825 | Nickel Alloys | |

| Duplex | Monel | Stellite / HR 160 | |

| Super Duplex | Hastalloy C-276 | ||

| P4, P5 |

Testing Facilities

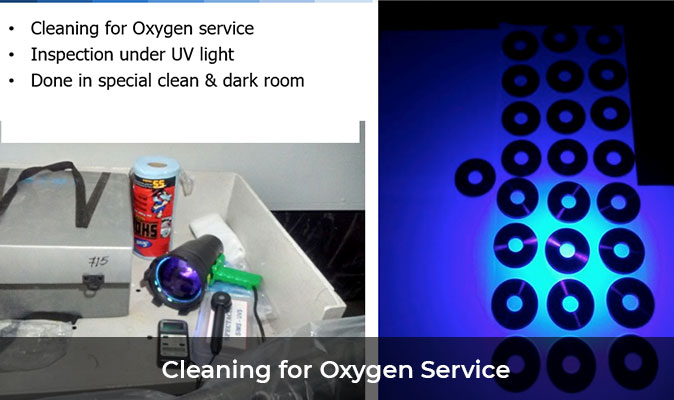

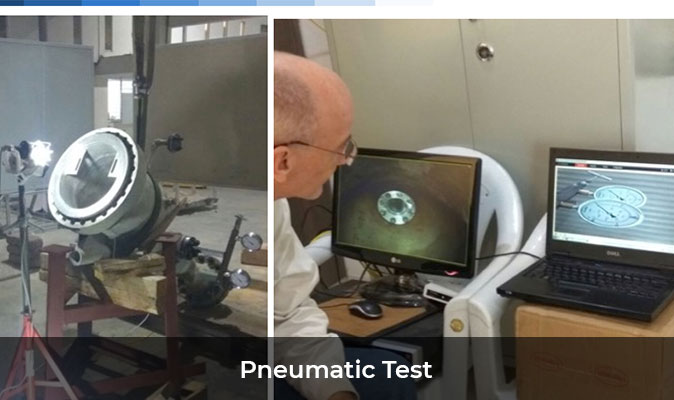

At PGSPL, Our commitment to safety and quality assurance is evidenced through our industry certifications & strict adherence to industry standards. Our Strength in Welding Dept is nourished by Highly Experienced BE-Metallurgist with IWE Certification. Our Quality Control Team are qualified with ASNT Level-II Certifications in PT/MT/UT/RT. We carry out the complete range of Non Destructive tests & Destructive Test like Tensile, Bend, Impact, all scales of Hardness, etc as per various National & International Standards.. (Refer attach documents for various test facilities).

Welding & Quality

State of the Art welding machines available for carrying out various welding processes in the workshop as well as at Site. Welding machines of known brands like Miller, Kemppi, etc (Pulsed MIG, AC/DC-TIG, etc) are available. Welding Process regularly carried out are GTAW, SMAW, FCAW, SAW. Autogenous TIG, Machine FCAW, and Custom-made Welding Automation are being carried out In-House. More than 55 Procedure Qualification available covering the various Base metal and Welding Process combination

Welding Process regularly carried out are GTAW, SMAW, FCAW, SAW. Autogenous TIG, Machine FCAW, and Custom-made Welding Automation is being carried out InHouse

| Welding Qualifications | |

| Stellite 6B | HR 160 |

| Stellite 6 Weld Overlay | P5 + Inconel Buttering |

| Stellite + SS Welding | Stainless Steel- 304, 304L, 316L, 321, 310,410 |

| Inconel 617 | Super Duplex 2507 |

| Inconel 617 + CS | Stellite Overlay of Pipe ID |

| Inconel 617 + Inconel 800 | SS Overlay of Pipe ID |

| Incolloy 800 | Aluminum 6061 |

| Inconel 617 + HR 160 | Carbon Steel |